About zigzag farrowing.

Pig farrowing crates arranged in a zigzag pattern in pens on floors that are part-concrete and part-slatted can give excellent results. Zigzag farrowing pens offer several advantages, including that:

Pig farrowing crates arranged in a zigzag pattern in pens on floors that are part-concrete and part-slatted can give excellent results. Zigzag farrowing pens offer several advantages, including that:

- they make maximum use of available floor area

- part-slatted pens fitted with zigzag crates are cleaner and drier

- the creep area is roomier.

A lane at the rear of the pens can overcome the disadvantage of restricted access to the pen corner opposite the creep area and provide good access to the rear of the sow at farrowing.

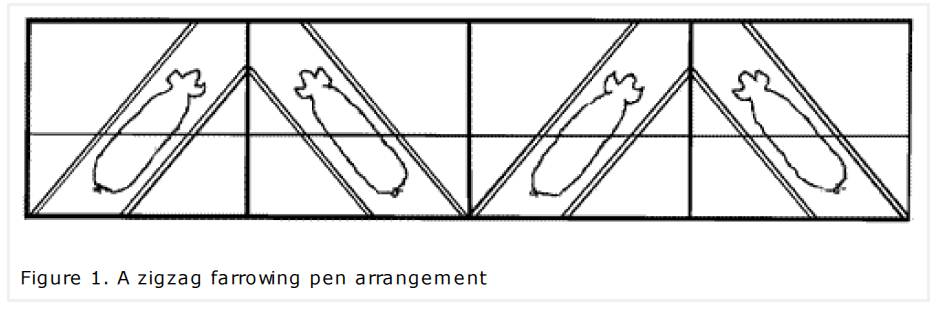

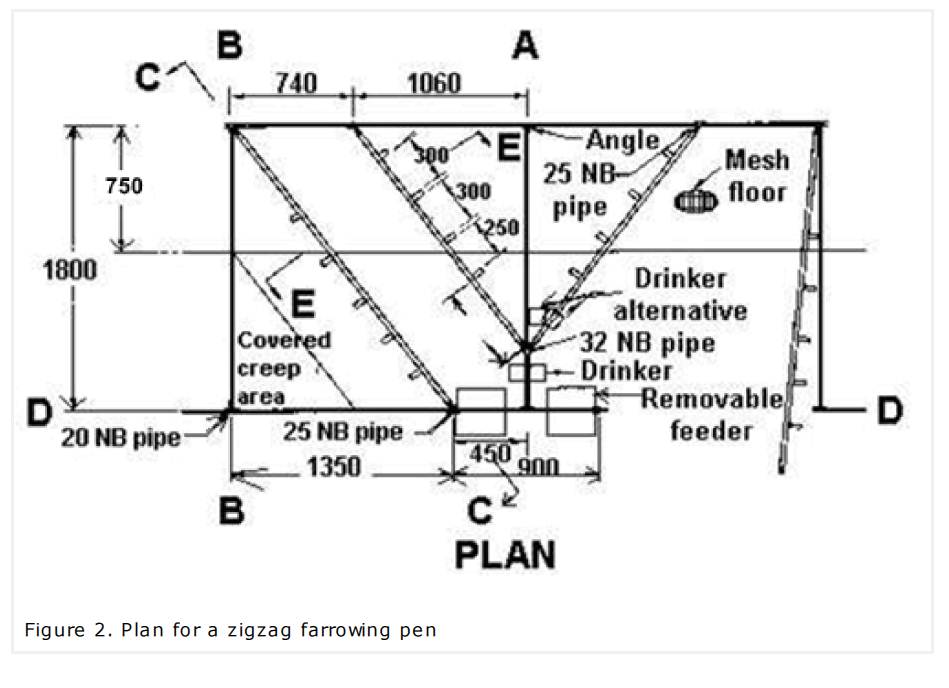

Layout and dimensions are critical factors in ensuring that zigzag farrowing pens work well. You can achieve effective results by arranging zigzag pens as shown in Figure 1, allowing an effective length of 2000 mm* for the sow, with adjacent creep areas and sows in crates facing similar pens across a laneway. The ‘all-in, all-out’ system, which uses pens in separate rooms to hold each weekly (or other time period) batch of farrowings, is strongly recommended for units with more than 200 sows and potentially for units with more than 100 sows.

*The ‘Model code of practice for the welfare of animals - pigs’ (3rd edition) outlines the minimum space requirements, crate dimensions, and other standards and recommended practices for farrowing pens.

Farrowing crate.

The farrowing crate comprises two parallel hurdles that run from corner to corner in the square-shaped pen.

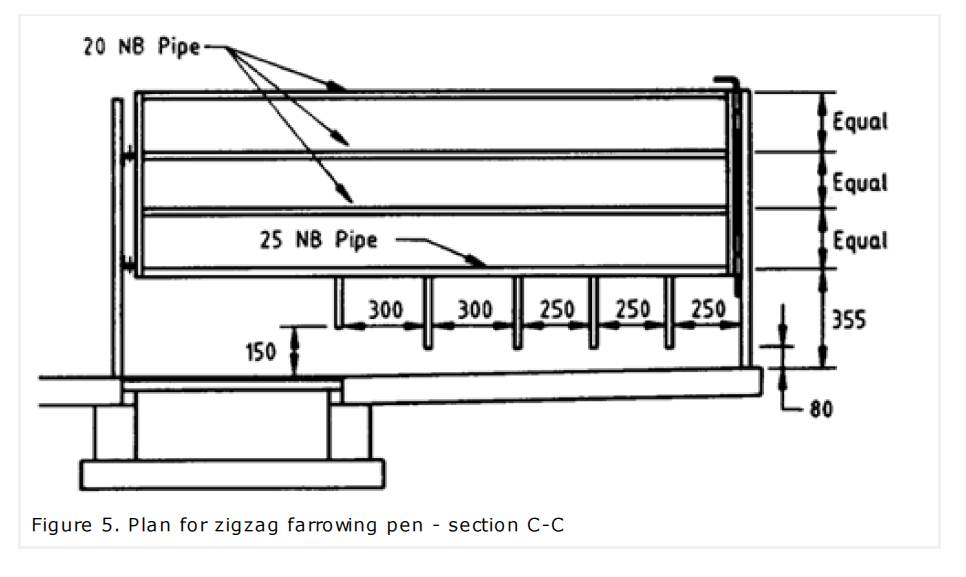

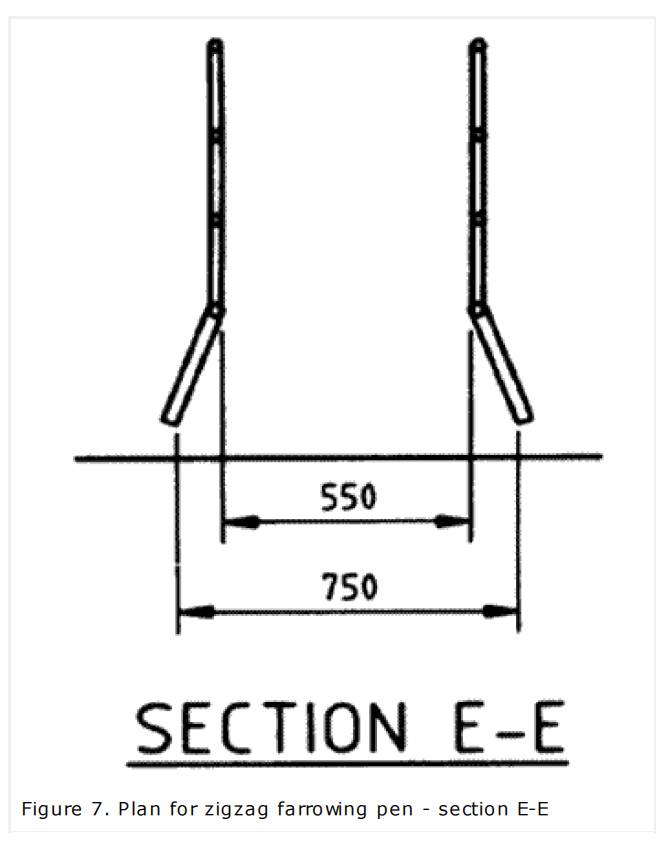

One hurdle is fixed and the other is hinged at the back wall to enable the introduction or removal of the sow. Both hurdles should be removable, making the pen easier to clean between litters. The bottom rail may be either fixed (expanded) or adjustable. If the height of the lower rails is adjustable, it should be possible to adjust to between 165 and 215 mm from the floor. This can be done with yokes and bolts, and pipe clamps, or by altering the height of the entire hurdle at the hinges. If the bottom rail is fixed, as an expanded rail, it should be at the same height and distance apart from the rail above, and the same distance from the opposite bottom rail as the prongs shown in Figure 7. The expanded bottom rail directly substitutes for the prongs and is easier to clean.

The minimum crate width for the sow is 500 mm for new installations, measured at no more than 450 mm from the floor level.

A detachable jump bar may be fitted over the front part of the farrowing crate to prevent the sow from mounting the pen front or hurdles, particularly while awaiting feed. This reduces the risk of the sow trampling piglets and damaging fittings.

A rump rail or breech bar (which can be a gate of vertical bars between horizontal bars) should be attached between the lower rails at the rear of the crate to keep the sow’s hindquarters clear of the back wall during farrowing, and give newborn piglets room to move after birth. It can then be removed.

Floors.

In part-slatted farrowing pens, a continuous polythene membrane must be installed beneath the concrete slab to prevent moisture rising through the concrete, and making the floor cold and damp.

The recommended fall in the concrete floor towards the manure trench at the rear is 1:40. Gentler slopes than this create problems with drainage, while steeper falls may mean excessive variation in clearance under the hurdles.

A strong, durable floor may be achieved with 30 MPa concrete and F62 reinforcing mesh. No admixtures or fly ash should be used as they may reduce the concrete’s durability. The floor surface should be finished to a smooth but not too slippery texture. The best finishing method will depend on the size distribution of the sand particles in the mix.

Slatted manure trench.

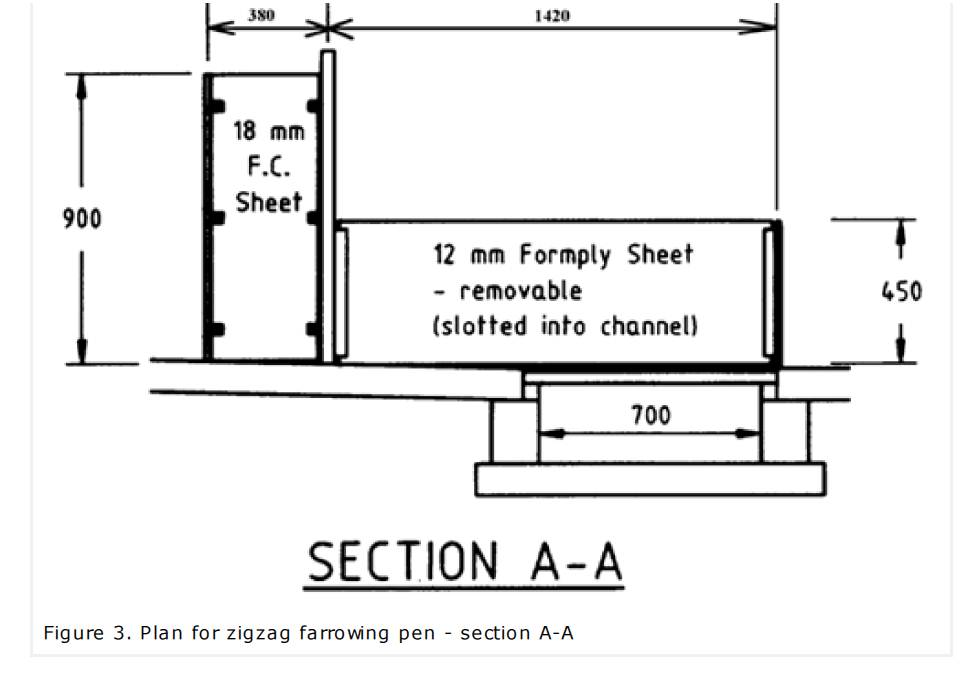

A trench width of 700 mm is recommended with 25 mm supporting ledges on either side to give 750 mm of slat width. A trench depth of 200 to 300 mm is recommended. A slightly wider trench that extends under the back panel at the rear of the sow will assist with walkway cleaning.

Welded steel mesh slats are most suitable, and 6 mm wires at 10 mm intervals on cross wires every 150 mm give effective results, though woven wire of similar dimensions is also satisfactory. Steel slats can be made up on the farm.

Plastic slats are satisfactory as they are warm and easy to clean. Sometimes plastic-covered steel meshes are difficult to clean and lack durability.

Plastic slats are satisfactory as they are warm and easy to clean. Sometimes plastic-covered steel meshes are difficult to clean and lack durability.

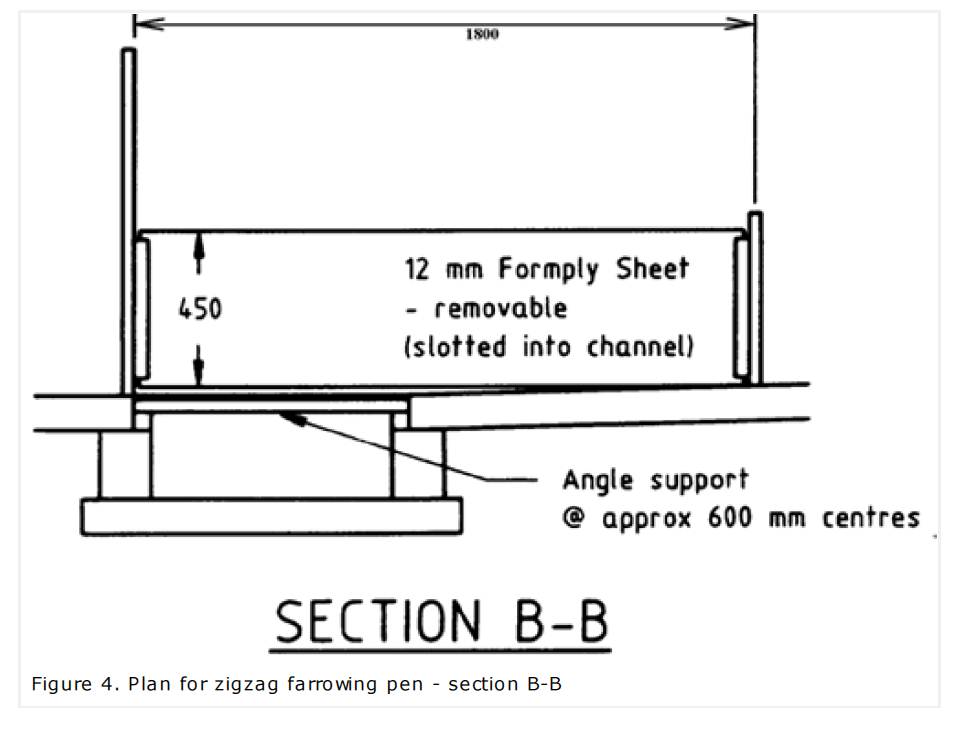

Slats or slat panels should be fitted in lengths corresponding to the pen width for easy removal and cleaning. As slatted mesh panels need support, lengths of inverted 50 mm angle iron or 25 mm galvanised pipe at 600 mm intervals are generally used.

Pen divisions.

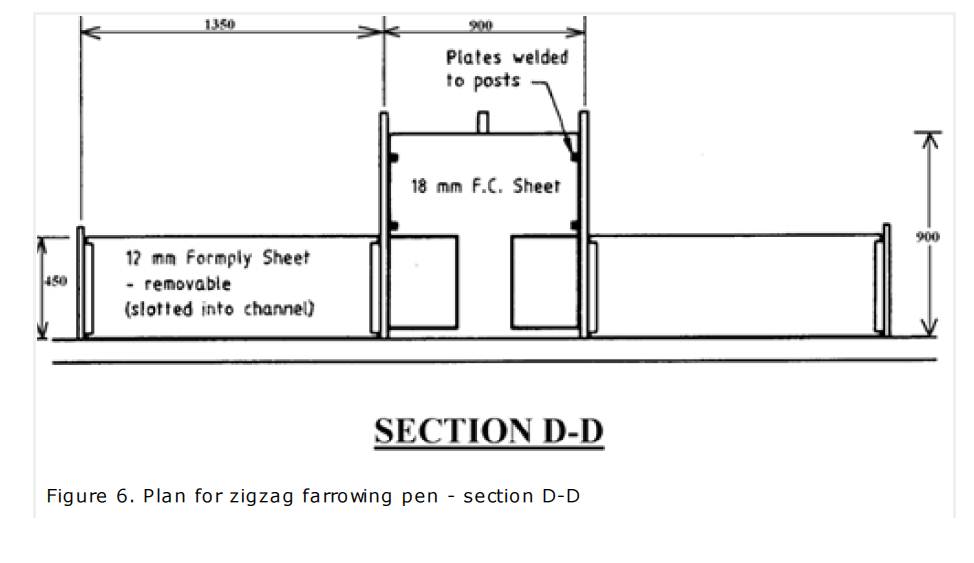

Fully compressed fibre cement sheeting is suitable for removable pen divisions (as shown in Figures 2 to 7). Other materials, such as plywood or sawn timber, can also be used. Polypropylene and recycled plastic boards perform well as they are warm and easy to clean. The pen front should be removable to permit pigs to enter or exit as required. It can be dropped into vertical guides or pinned at both ends.

Tilt-up or cast-in-place concrete partitions can also be used successfully. However, allowance must be made for their thickness, and the dimensions shown in Figures 2 to 7 should be regarded as internal. Concrete panels result in a layout that is difficult to alter.

The pen sides and the removable front may be 450 mm high if four-week weaning and/or litter mixing is practised there. Otherwise, divisions may be up to 600 mm high. The fixed side and front enclosing the sow must be at least 900 mm high.

Water and feed.

Ensure the type and placement of feeders and drinkers clear the length of the sow.

The combination bowl and nipple drinker is satisfactory for watering sows in zigzag pens. It is mounted on the pen division near the sow’s head, and the underside is 25 to 50 mm clear of the floor. Alternatively it can be mounted so it projects through the shorter fixed hurdle or is bolted to the hurdle. The drinker should be fitted as close to the trench as possible to allow spillage to drain away rapidly.

Nipple drinkers are unsuitable for watering sows in part-slatted pens as too much water spills over the solid floor. However, if they are mounted over the slats, they are recommended for low-pressure watering of sucking pigs. This enables piglets to familiarise themselves with the most commonly used watering device in weaner and grower pens.

The feed is placed in a trough at the front of the crate. You can made a triangular trough on the floor by constructing a nib wall 120 mm high; the other two sides are formed by the pen walls.

Heating.

Heat lamps mounted on a triangular hover board over the corner creep area can provide localised warmth for very young piglets. Underfloor heating in the creep area is a satisfactory alternative if used with a hover.

Localised creep heating is desirable, even in space-heated farrowing sheds to give piglets the warmest and safest area in the pen away from the sow, who requires a cooler temperature.

Author:

Ken Casey.