A typical sample of machine-harvested coffee

Machine-harvested coffee requires a specialised processing system. Such a system has been developed in Australia and can produce high quality coffee from prime cherry regardless of the levels of immature cherry harvested.

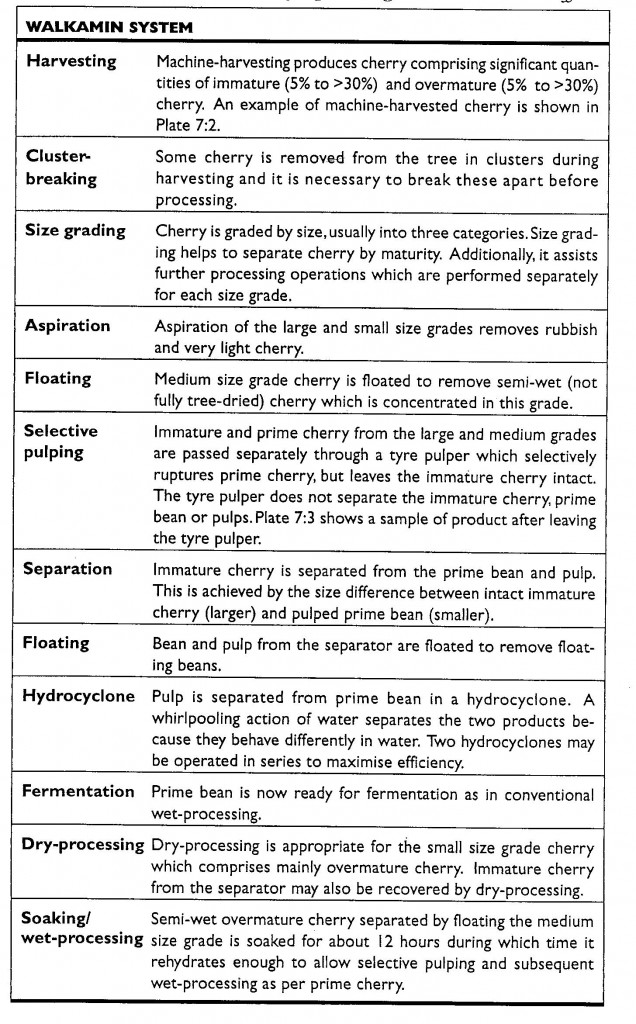

Limits to the amount of immature cherry handled by the system will be imposed by the economics of harvesting high levels of immature cherry rather than by performance limitations of the system. In developing a system for the wet-processing of machine-harvested coffee, Australian researchers have taken a new approach. The key elements of the Walkamin system are innovative and unconventional for coffee processing. The basic stages of this processing are described in the Walkamin system table below.

The water requirements and the pollution potential of wet-processing are considerations in the design and siting of processing factories. The pilot system at Walkamin Research Station uses about 10,000 L/h ofwater to process machine-harvested cherry at 6,000 kg/h. This does not include fermentation and washing which may require an additional 4,000 to 10,000 litres of water for each tonne of dry green bean, depending on the sophistication of the system used. The pollution potential of waste water is significant. Treatment includes solids removal, settlement and subsequent pondage, or land-based disposal. The design and management of treatment works requires professional expertise and needs to comply with relevant authority regulations. Pulp, discarded cherry and solids separated from waste water are commonly returned to the plantation by spreading under trees or between rows (mulching).

Size grading

The first stage of the Walkamin system is size grading. Before actual sizing, clusters of cherry are broken to avoid misplacement of small immature cherry in the larger size grades. There is a general relationship between cherry maturity and size which allows significant maturity grading of cherry on the basis of size. After the cherry develops to the hard green stage, size remains relatively constant for about two and a half months as the bean matures. The cherry flesh (pulp) then expands and colours to the prime red stage. The life of cherry in prime condition is relatively short. The pulp dehydrates quickly and the cherry shrinks, finally reaching the fully tree-dried stage which is significantly smaller than hard green cherry. Size grading has four main advantages.

- Prime cherry is concentrated in the large grade. Tree-dried and most overmature cherry is eliminated from this grade.

- Small immature cherry is removed from the large and mediumgrades. This is important because this cherry is similar in size to prime bean (after pulping). Small immature cherry is extremely difficult to separate if allowed to contaminate prime bean.

- Tree-dried cherry is concentrated in the small grade. It has been separated without wetting.

- More uniform cherry grades are obtained for subsequent processing operations.

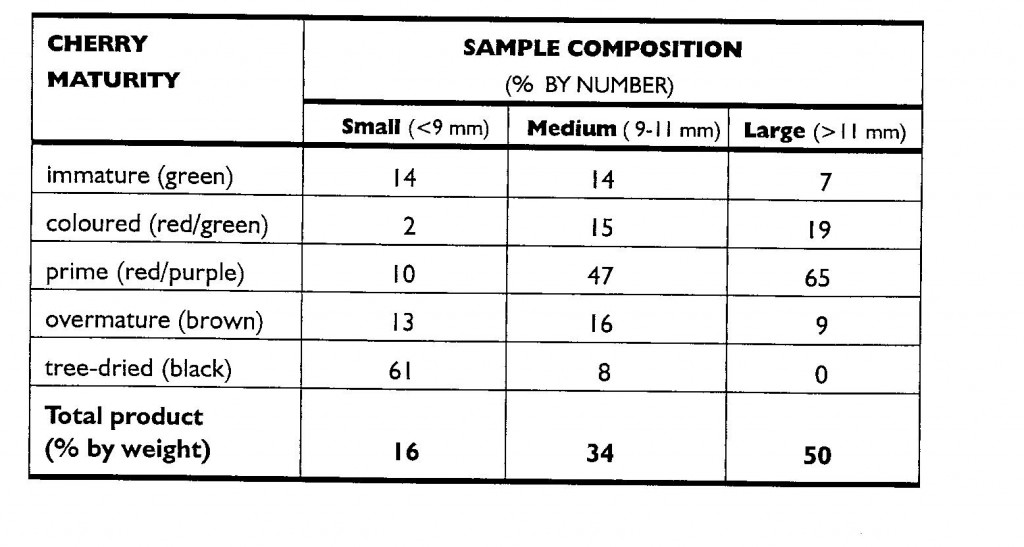

The results of size grading an actual sample of machine harvested coffee are shown below:

Composition (by maturity) of a machine-harvested, size-graded sample of coffee cherry

Traditional float separation of overmature cherry wets the product and may also incur significant losses of primary cherry

An important advantage of size grading is that tree-dried cherry is dry separated. While float separation could have been used at the outset, this wets the cherry, resulting in significant water uptake. Subsequent drying of float-separated (wetted) product requires extra energy and considerable management to avoid the risk of hazards such as mould development. The urgency of drying and the drying requirement of dry-separated overmature cherry is considerably less and the drying management is simplified. This procedure also avoids the loss of floating but otherwise sound prime bean, which can be a potentially significant loss in some seasons. Sound prime cherry will float when just one of the beans is improperly developed or air pockets occur in the cherry (see photo right). Some drying options for overmature cherry are:

Full sun-drying, usually on the ground

This is cheap but requires a significant degree of management during the relatively lengthy drying period (usually at least one to two weeks depending on weather conditions). Drying on black plastic is common practice but should be avoided. Elevated drying racks which allow air circulation are ideal but more costly. Drying on shadecloth on the ground is a reasonable compromise. Overseas, hard earth or concrete drying areas are commonly used.

Mechanical drying

This requires considerable drying capacity due to the quantity of material. However this is compensated by the relative dryness of the initial product compared with wet parchment coffee. Also, the drying regime may be relatively unsophisticated and higher temperatures may be used.

In North Queensland, where the processing system was developed, cherry is size graded into small (<9 mm), medium (9-11 mm) and large (>11 mm) grades. However the screen aperture sizes selected are determined by the particular range of cherry sizes for that harvest. In general, cherry size is determined by the cultivar, the environment and growing conditions.

Rotary sizing screens (trommels) are an effective way of size grading cherry because they are less prone to blockage than other methods of screening. They can also incorporate a mechanism for breaking clusters before sizing.

Aspiration

Aspiration removes rubbish (leaves, sticks and foreign matter) and very light (old, overmature and insect damaged) cherry from the small and large size grades by using a controlled air stream. These products have different densities and aerodynamic properties to immature and prime cherry. Careful size grading beforehand greatly increases the effectiveness of aspiration.

Source

Craig Lemin

The Walkamin system for processing machine-harvested coffee