Coffee harvesters, like many other fruit and nut harvesting machines, incorporate vibration to remove the cherry. The efficiency of these harvesting systems is directly related to both the way the fruits are attached to the branch(e.g. singly or in clusters) and the force needed to pull the fruit from the lateral or branch, known as the fruit removal force (FRF).

Coffee harvesters, like many other fruit and nut harvesting machines, incorporate vibration to remove the cherry. The efficiency of these harvesting systems is directly related to both the way the fruits are attached to the branch(e.g. singly or in clusters) and the force needed to pull the fruit from the lateral or branch, known as the fruit removal force (FRF).

Fruit removal force (FRF) of coffee the FRF of coffee depends on cherry maturity, cultivar, environmental conditions under which it is grown and, to a lesser extent, the environmental conditions at harvest time. Unfortunately, the FRF of coffee is many times greater than other fruit of similar size, so coffee is significantly harder to harvest mechanically.

Cherry Clusters:

Fruit can be attached to a bush as single fruit, bunches or as clusters on the stem. Coffee cherry grows around the laterals in tight clusters, so can be very hard to remove even with direct contact by harvester fingers. Tall cultivars have larger spaces between nodes and usually fewer cherries per node than semi-dwarf varieties. This more open structure means cherry can be more readily removed individually, rather than in clusters. Harvesters can, therefore, potentially be more selective when harvesting tall varieties than semi-dwarf varieties.

When looking at the suitability of a cultivar for machine-harvesting it is important to consider not only yield potential, but also cherry cluster arrangement a FRF as these can significantly influence ease of harvest and cherry recovery.

Summary:

- Fruit Removal Force (FRF) is an important characteristic to consider when evaluating the suitability of a cultivar for mechanical harvesting. FRF of mature cherry dictates the harvester’s ability to remove the cherry without damaging the tree (eg. excessive leaf removal and bark damage). FRF characteristics significantly influence the harvester’s ability to selectively remove prime cherry.

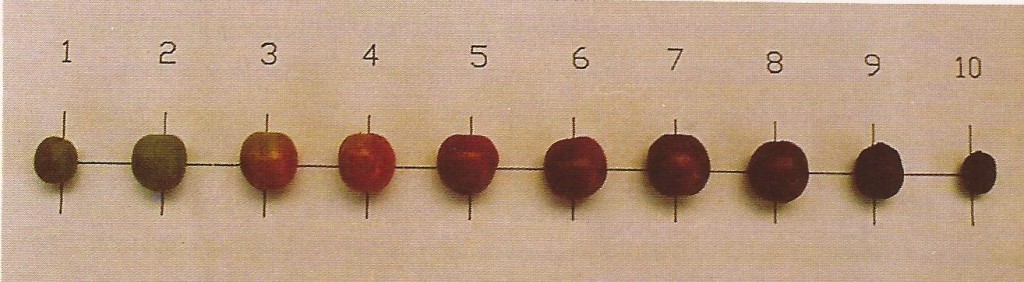

- To recover as much cherry as possible and minimise tree damage, it is essential to delay machine-harvesting until as much of the cherry as possible has reached a maturity index range of six to eight (see cherry ripening stages below).This ensures a low FRF while still harvesting cherry which will produce a high quality final product.

- The tight packing of the cherry clusters means high yielding semi-dwarf varieties can be difficult to harvest unless harvesting is delayed to allow most of the cherry to become very mature and easy to remove (low FRF).

The ten stages of cherry ripening from immature green to overmature (mbuni) The prime ripe state necessary for maximising cupping quality includes stages four to eight.

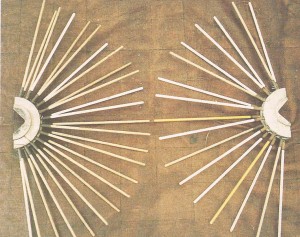

Hands on harvester shaker shaft

The harvester’s shaker system removes coffee cherry by a combination of direct contact by the fingers and vibration of the tree, particularly along the branches or laterals. Factors which affect the performance of the harvester are complex, but the harvester can be adjusted to match harvesting conditions. Operations which can be adjusted include:

• shaker frequency (how fast the shakers vibrate)

• forward operating speed

• amplitude of shake (how far the ends of the fingers oscillate)

• loading of the shakers against the tree

• spacing of the fingers on the shakers

• type (composition) of fingers.

Shaker frequency and forward speed:

Shaker frequency and forward speed are the two adjustments readily manipulated by the operator. Shaker speed or frequency is the most important adjustment affecting the performance of the harvester, as the energy input into the shakers is approximately proportional to the square of the shaker speed. Doubling both shaker speed and forward speed means that each tree receives the same number of shakes from the shakers, but each shake contains four times as much energy, thus more vigorously shaking the tree. If all other settings are kept the same, increasing shaker speed therefore increases total cherry removal, reduces selectivity and increases tree damage.

Amplitude of shake:

The amplitude of shake of the fingers, in conjunction with the shaker loading, affects the efficiency with which vibration energy is transferred to the tree from the shakers. To minimise tree damage it is normally desirable to operate the shakers at the lowest amplitude which will give effective cherry removal (typically 600 to 900cpm). The amplitude of shake of the fingers is determined by the mass and eccentricity of the rotating weights in the shaker drivers. Amplitude can therefore he adjusted by modifying the rotating weights. Such an adjustment can only be made by the manufacturer, and is therefore not adjusted during day to day harvesting. If it is necessary to operate the shakers outside the typical frequency range, the shaker weights may need to be modified.

Source:

Chris Norris