One pass harvesting:

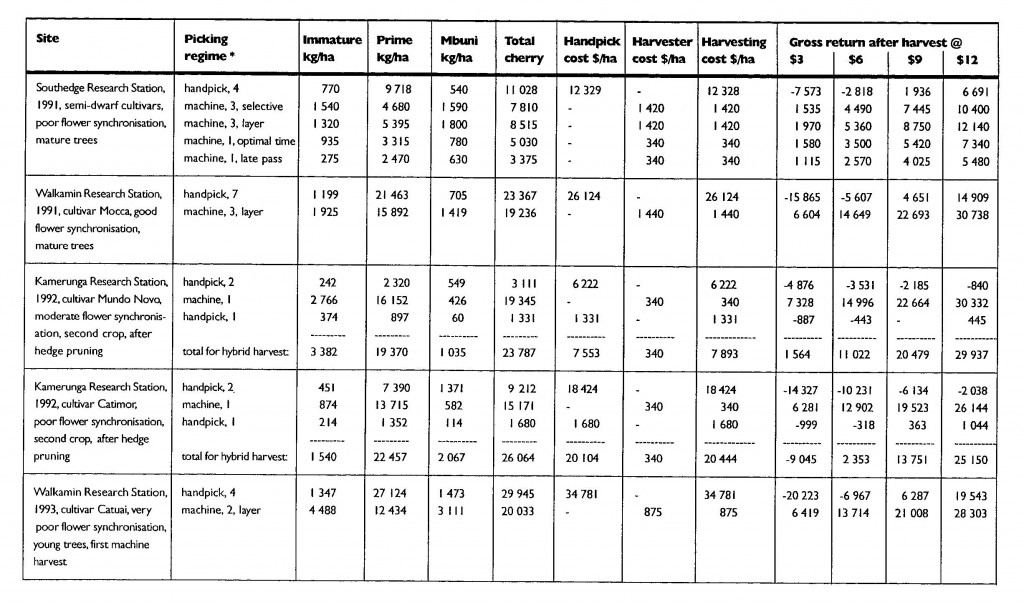

Due to the high cost and limited availability of harvesters, a one pass harvesting regime, producing predominantly prime cherry, has been the aim of many of the Australian coffee growers since the inception of the industry. Smaller growers in North Queensland delayed this harvest pass until little immature cherry remained on the trees to allow the harvested cherry to he processed with the conventional equipment developed for hand-picked cherry. One advantage of this strategy was low harvest costs because the advanced maturity of the cherry allowed for high harvester work rates. Unfortunately, yield data from experiments incorporating this treatment at Southedge Research Station ( see Table below, Southedge, late pass) and, more recently, at Walkamin, indicated that the total recovery is usually low, probably because of very high losses due to cherry becoming overmature and falling before harvest.

Due to the high cost and limited availability of harvesters, a one pass harvesting regime, producing predominantly prime cherry, has been the aim of many of the Australian coffee growers since the inception of the industry. Smaller growers in North Queensland delayed this harvest pass until little immature cherry remained on the trees to allow the harvested cherry to he processed with the conventional equipment developed for hand-picked cherry. One advantage of this strategy was low harvest costs because the advanced maturity of the cherry allowed for high harvester work rates. Unfortunately, yield data from experiments incorporating this treatment at Southedge Research Station ( see Table below, Southedge, late pass) and, more recently, at Walkamin, indicated that the total recovery is usually low, probably because of very high losses due to cherry becoming overmature and falling before harvest.

An alternative strategy developed to minimise these losses involves a single aggressive harvester pass, timed to maximise the recovery of prime cherry. If good flowering synchronisation occurs, the optimum time of harvest is when approximately 15% to 20% of the cherry is immature. Results of trials incorporating this strategy (see Table below, Southedge, one-pass) indicate significant gains in prime cherry recovery. The availability of processing equipment capable of processing harvested cherry with greater than 10% immature cherry is essential if using this harvesting strategy. The higher shaker energy used to remove the cherry in this strategy increases tree damage more than late pass harvesting.

While the advantage of a one pass, non-selective harvesting regime is low total harvest cost, this does not give maximum profitability. Trials at both Walkamin and Southedge (see Table below) demonstrated this.

Harvesting costs and recovery of coffee under different harvesting regimes. Refer also to the information below.

Picking regime*

This column indicates the type and number of harvesting passes made.

Labour productivity assumptions for hand picking:

Initial 25% of crop harvested at 50 kg/8 hour day (very selective picking, predominantly immature cherry on bush)

• Subsequent 35% of crop harvested at 100 kg/8 hour day (selective picking, greater proportion of mature cherry)

• Remaining 40% of crop harvested at 150 kg/8 hour day (little immature cherry - strip-picking techniques used)

• Labour costs of $12 hour are used

Recovery (based on trial results):

• Immature: 5.5 kg cherry gives I kg green bean - no commercial value

• Prime: 6.5 kg cherry gives I kg green bean ? valued at $3, $6, $9 and $ 12/kg green bean, representing the range of prices achieved

by growers

• Mbuni: approx. 3 kg cherry gives I kg green bean - valued at 50% of the selected value of prime green beans

Layer harvesting:

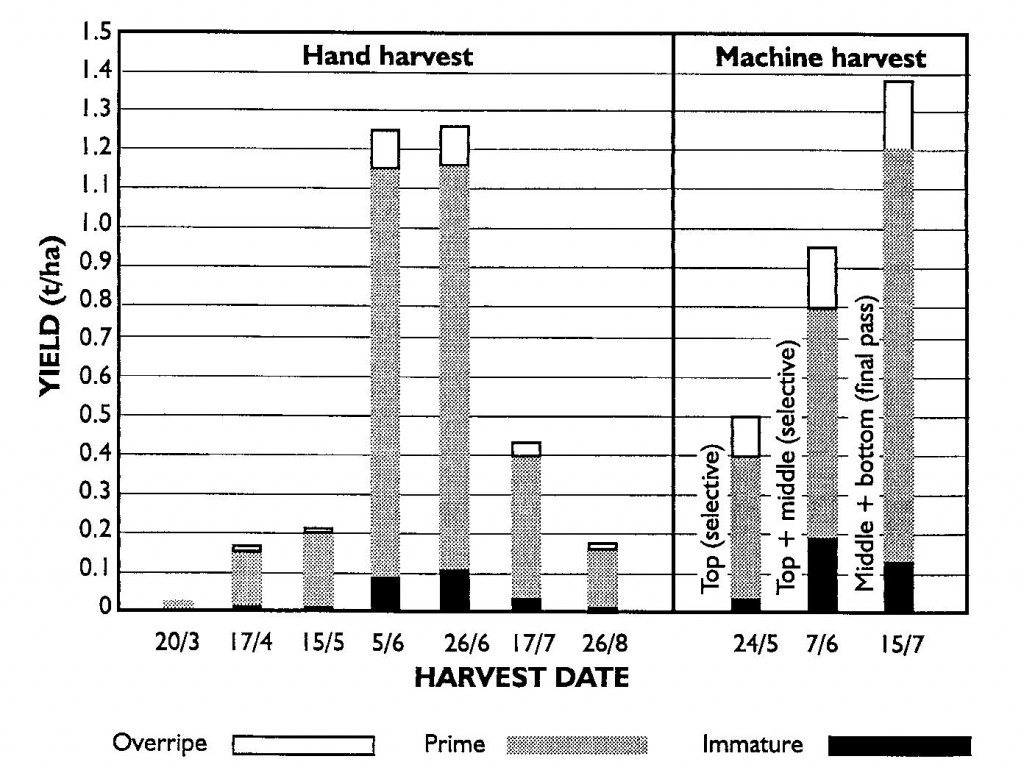

As indicated in other mature bearing trees articles, coffee cherry typically ripens in a distinct pattern from the top of the tree down, particularly when a high degree of flowering synchronisation has been achieved in mature trees. Thus, cherry at the top of the tree (typically 25% to 30% of the total cherry on the tree) is frequently almost completely mature before significant ripening has occurred in the lower sections of the tree. Because of its exposed position, the cherry at the top of the tree has a shorter life than the more protected cherry in the lower section of the tree. If harvesting is delayed until cherry in the lower section of the tree matures, the cherry in the top section will be tree-dried and may have fallen before harvest.

Selective harvesting has often been attempted to recover this cherry, with disappointing results. The mature cherry is only a small proportion of the total cherry, and shaker settings aggressive enough to remove a worthwhile proportion of it mean that large amounts of immature cherry are also removed from the lower sections of the trees.

Harvesting trials led to the development of a layer harvesting technique, where sections of the harvester shakers are fitted to coincide only with the location of mature fruit, thus resulting in a top to bottom harvesting sequence. The first selective pass of the top third of the tree typically begins when this section holds less than 20% immature cherry. The second pass is then delayed until the bulk of the cherry in the middle section of the tree is fully mature. Shaker fingers fitted to match the top and middle sections of trees remove any remaining cherry from the top section and a large proportion of the cherry from the middle section. The third and final pass incorporates fingers fitted to harvest the middle and lower sections of the tree. The extended cherry life in these sections of the tree means this pass be delayed until all cherry is very mature, allowing easy removal.

Yield of immature, prime and overmature cherry from cultivar Mocca at Walkamin, North Queensland, after hand harvesting and machine harvesting (selective layer harvesting)

Coffee being picked at a 100yr old estate that has been owned by four generations of the Zamora family

For the semi-dwarf varieties, recovered prime cherry was 61% of the hand-picked yield, and total recovery of all grades was in excess of 84% of the total hand-picked yield for both cultivar types.

Trials and commercial experience in North Queensland have indicated significant quality, recovery and profit advantages in layer harvesting and, as a result of this Australian research, the technique is now being adopted by some large producers in Brazil. To date a major disincentive to the adoption of the technique has been the significant time required to remove and refit shaker sections. Easy removal of sections of the shakers is now a feature of modern harvester design.

Source:

Chris Norris