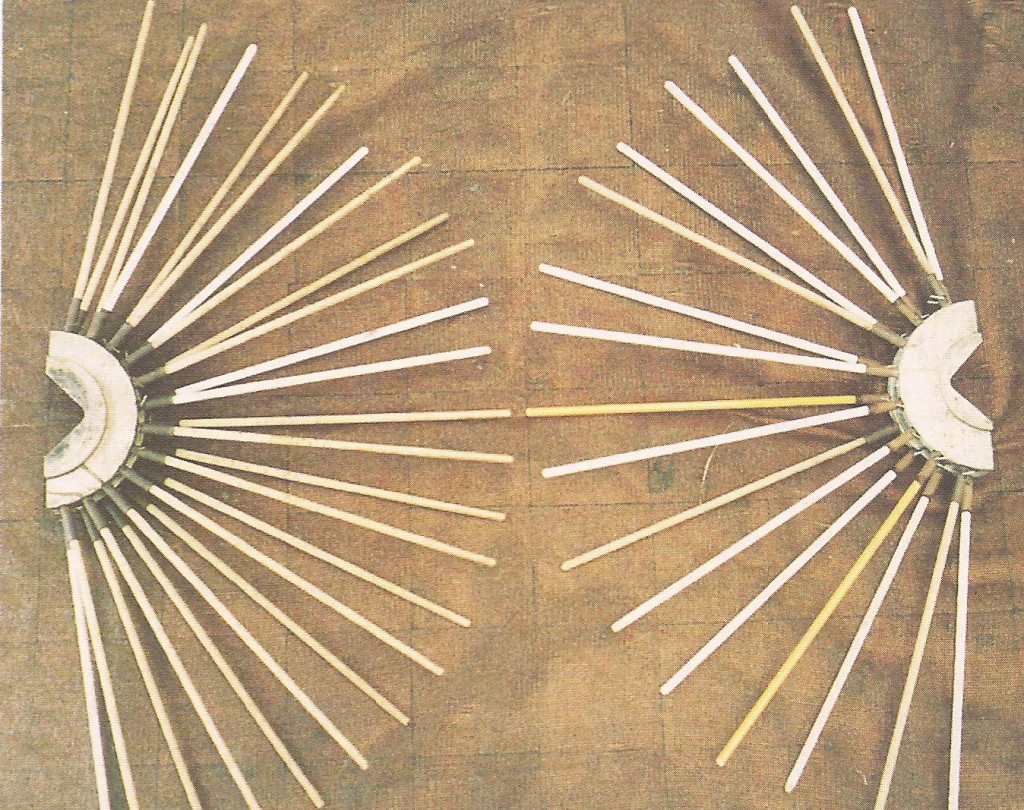

Fitting 'hands' with more fingers (left) and/ or closing up the distance between hands on the shaker shaft, enhances the performance of the harvester under difficult harvesting conditions, such as harvesting young trees. Care must be taken to ensure the total number of fingers fitted does not exceed the number originally fitted by the manufacturer

Research on machine-harvesting of coffee was undertaken as part of the Australian coffee research and development program to address the numerous problems Australian coffee pioneers faced while trying to develop satifactory harvesting methods. This article investigates the findings and recommendations of researchers with regard to harvester performance, shaker set up and suitability under varying conditions.

Shaker Loading:

A system to ‘load’ the shaker fingers against the tree is one of the significant Australian developments in coffee harvesters. By loading the shakers against the tree, the vibration of the fingers is transferred into the tree structure more efficiently, thus removing more cherry indirectly than by direct finger contact. On larger trees, more aggressive loading is desirable than on smaller trees. Loading of the shakers is easily adjusted but usually only changed to suit major changes in harvesting conditions. Correct loading allows maximum cherry removal at the lowest possible shaker frequencies, thus reducing all types of tree damage.

Finger spacing:

On young trees, or under difficult harvesting conditions where FRF is very high, it is often difficult to achieve high levels of cherry removal without excessively damaging the tree. By installing modified shaker flanges with more fingers (see photo), and setting the flanges closer together, there are more opportunities for fingers to directly contact cherry rather than rely on vibration transfer through the tree. Increasing the number of fingers can give significant improvements in ripe cherry removal without increasing tree damage, because it allows the shakers to operate at lower frequencies.

This option of increasing the number of fingers is only relevant for coffee harvesters such as the DPI-developed Austoft coffee harvester where shakers are phased (i.e, shake in unison). In unphased machines, increasing the number of fingers increases tree damage. In order to avoid reducing the amplitude of shake the total number of fingers on the shaker system should not significantly exceed the number originally fitted to the machine. Increasing the number of fingers in one section of the shakers (e.g. the bottom of the shakers to harvest small trees) is usually compensated for by removing the fingers from another section of the shakers.

Finger composition:

The composition of fingers is usually only changed to overcome an operational difficulty such as finger breakage. Within broad limits the resin and fibre used in the fingers will not change the performance of the harvester significantly, but may significantly affect the life expectancy of the fingers.

Summary:

Harvesters remove coffee cherry by a combination of direct contact of the fingers against the cherry and vibration transfer through the tree structure.

Harvesters remove coffee cherry by a combination of direct contact of the fingers against the cherry and vibration transfer through the tree structure.

- Forward speed and shaker operating frequency are the two adjustments most readily manipulated by the operator to match the harvester to the harvesting conditions.

- Correct loading of the shakers against the tree allows maximum cherry removal at the lowest possible shaker frequencies, thus reducing all types of tree damage.

- Under some conditions, adjusting the amplitude of the shaker oscillations can be used to enhance performance.

- Increasing the number of fingers in the shakers can enhance harvester performance in difficult harvesting conditions and reduce damage to young trees.

- The composition of the shaker fingers can have a significant impact on their expected life, but only a limited impact on harvesting performance.

Source:

Chris Norris