Alligator production in environmentally controlled houses is similar in intensity to production in poultry and swine houses. As with any highly intensified agriculture activity, alligator farming has a high degree of risk and demands special management skills.

Alligator production in environmentally controlled houses is similar in intensity to production in poultry and swine houses. As with any highly intensified agriculture activity, alligator farming has a high degree of risk and demands special management skills.

Management skills in alligator production are particularly critical since these animals have been removed from the wild only recently and are not truly domesticated.

Essential management skills for the alligator producer are providing proper physical conditions, adequate nutrition, and a non stressful environment.

This fact sheet outlines basic management practices for growing alligators from hatchlings to harvest/market size.

Grow-out facilities:

Many different designs of growout facilities have been built. Grow-out buildings are heavily insulated concrete block, wood or metal buildings with heated foundations. The foundation is a concrete slab laced with hot water piping or, less commonly, electric heating coils.

A constant temperature is maintained in the building by pumping hot water through the pipes. The slab is poured over insulation board to reduce heat loss. Some grow-out houses are earth-bermed to reduce further heat loss. Pools, drains and feeding areas are designed into the foundation before the concrete is poured.

Approximately one-third of the pen is above the normal . water level and is used as a feeding and basking deck. The remaining two-thirds is a pool usually about one foot deep at the drain. The pool bottom slopes to a central drain to facilitate cleaning.

Separate pens are constructed within a building using concrete block walls three feet tall. Pens can be made almost any size. In general, smaller pens are used for rearing small alligators and as the alligators grow, pens become progressively larger.

Many producers stack small fiberglass or metal tanks above the larger floor pens for housing small gators. This greatly increases the utilization of space and heat within the grow-out houses. Pens and tanks must be “climb-proofed” to prevent nimble young gators from escaping.

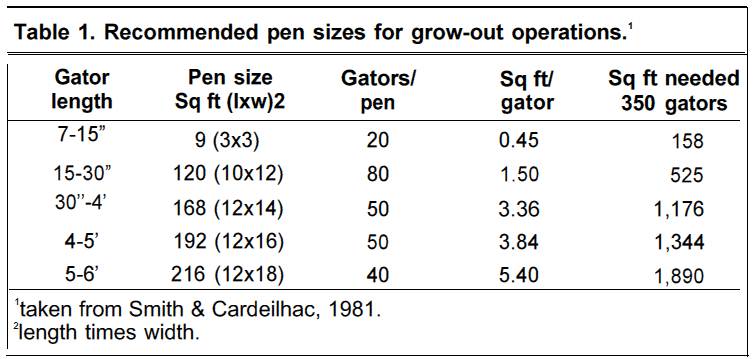

Table 1 gives examples of pen size to alligator size and corresponding densities.

Many producers construct a couple sizes of grow-out pens and simply reduce the density by moving the animals as they grow. A commonly used stocking regime is:

- 1 square foot per animal until 2 feet in length.

- 3 square feet per animal until 4 feet in length.

- 6 square feet per animal to 6 feet in length.

A common construction plan includes a building containing approximately 5,000 square feet (e.g., 33 x 150 feet) with an aisle down the middle and pens on either side. A 4-foot aisle leaves pens roughly 14 feet in width. Pen length is usually about 12 feet.

Three-foot high concrete block walls separate individual pens and pens from the aisle. Within the 12- x 14-foot pen is a 5- foot wide deck (i.e., 5 x 12 feet) next to the service aisle and a 9- foot wide pool (i.e., 9 x 12 feet).

Three-foot high concrete block walls separate individual pens and pens from the aisle. Within the 12- x 14-foot pen is a 5- foot wide deck (i.e., 5 x 12 feet) next to the service aisle and a 9- foot wide pool (i.e., 9 x 12 feet).

Food can be placed on the deck and the pen hosed clean from the aisle without entering it. The pool edge slopes rapidly to a depth of 10 inches next to the deck, and the pool bottom slopes from there to a 12-inch depth at the drain.

The drain runs the width of the pool. The pen is easily divided into two pens by the construction of a wall down the center. The large pen can hold around 160 two-foot or 50 four-foot alligators. The small pen can hold about 80 two-foot alligators. Some state laws require that alligators less than 2 feet long be held separately from those over 2 feet in length.

Another popular building design is a single “round house’’ design. Round house structures are 15 to 25 feet in diameter and are constructed as single pens. Many round houses are constructed from a single section and roof component of a prefab metal silo (used for grain storage).

Round houses have also been built from concrete blocks. The round concrete slab on which the house sets is sloped (about 10:1) from the outer edge to a central drain. The round house is filled with water to leave about one-third of the outer floor above the water level.

Producers like this single pen design because it does not disturb alligators in other pens during routine feeding, cleaning and handling operations. Part of any alligator facility design is a room that holds the heating system.

The heating system usually consists of water heaters and pumps to circulate warm water through the concrete slab. Warm water is needed to warm the building and to clean the pens. Some heating systems consist of several industrial size water heaters.

Other systems consist of a flash type heater (i.e., the type used in car washes) to heat water for cleaning and standard water heaters to circulate warm water through the slab. Both systems use thermostats to turn on heaters and circulation pumps.

The temperature in grow-out buildings must be maintained between 86 and 88°F for optimum growth. Grow-out buildings rarely contain windows, and many producers prefer no skylights. In fact, most animals are kept in near or total darkness except at feeding and cleaning times.

Author:

Michael P. Masser