Coffee drying

An important part of the coffee research and development program has been the development of a processing system for the mix of immature, prime (ripe) and overmature cherry typical of machine-harvested coffee. Conventional processing techniques and equipment are only appropriate for selectively hand-picked, prime cherry. The significant limitations of such systems experienced during the research program and by the pioneers of mechanised coffee production in Australia, resulted in the development of a processing system specifically designed for machine-harvested cherry.

Conventional coffee processing

Processing is the most important factor in determining coffee quality. It cannot improve the inherent quality of coffee, but poor processing can lead to serious quality faults.

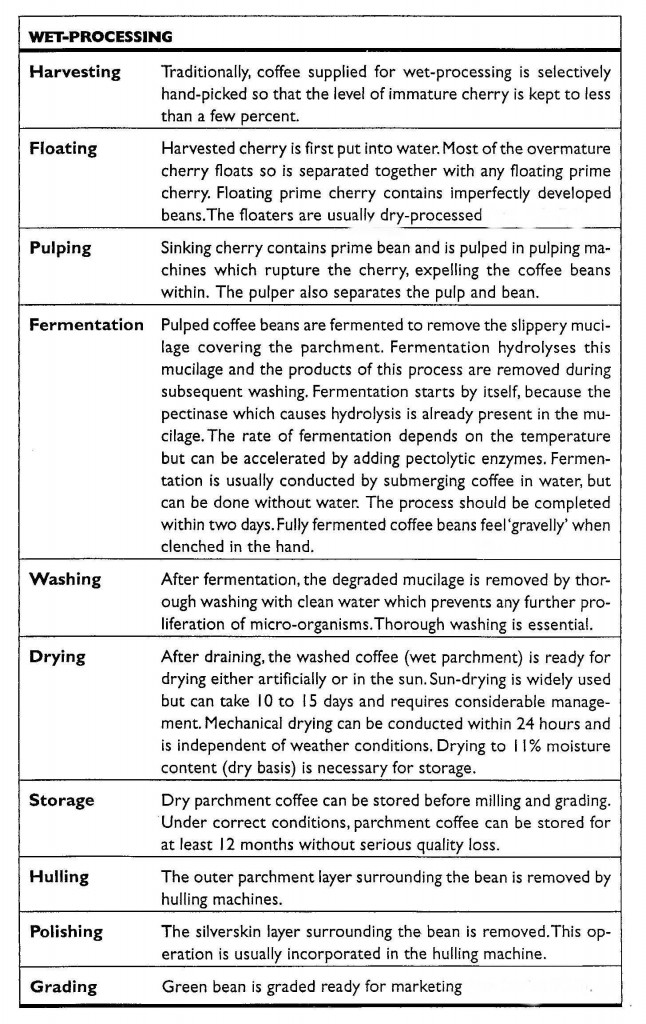

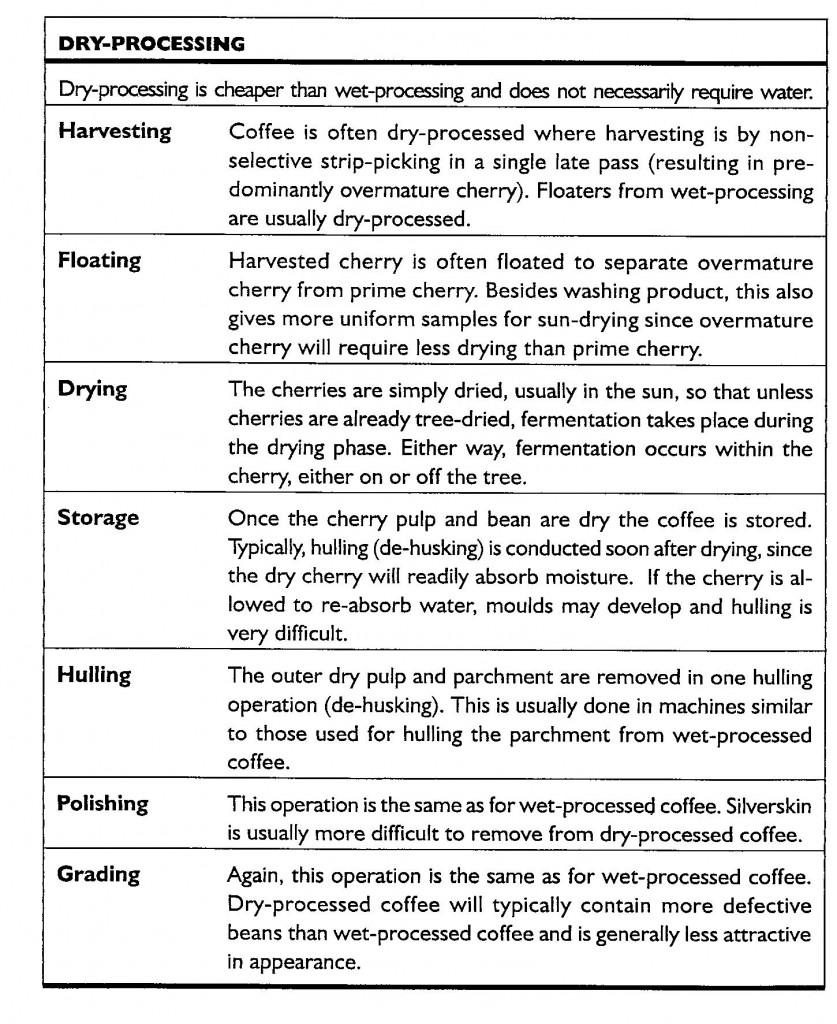

Coffee is processed by either the wet or dry methods, and the basic procedures in each of these are shown in Tables 1 and 2 below.

Stages in the wet method of coffee processing

Table 1 Stages in the wet method of coffee processing

Stages in the dry method of coffee processing

Table 2 Dry-Processing

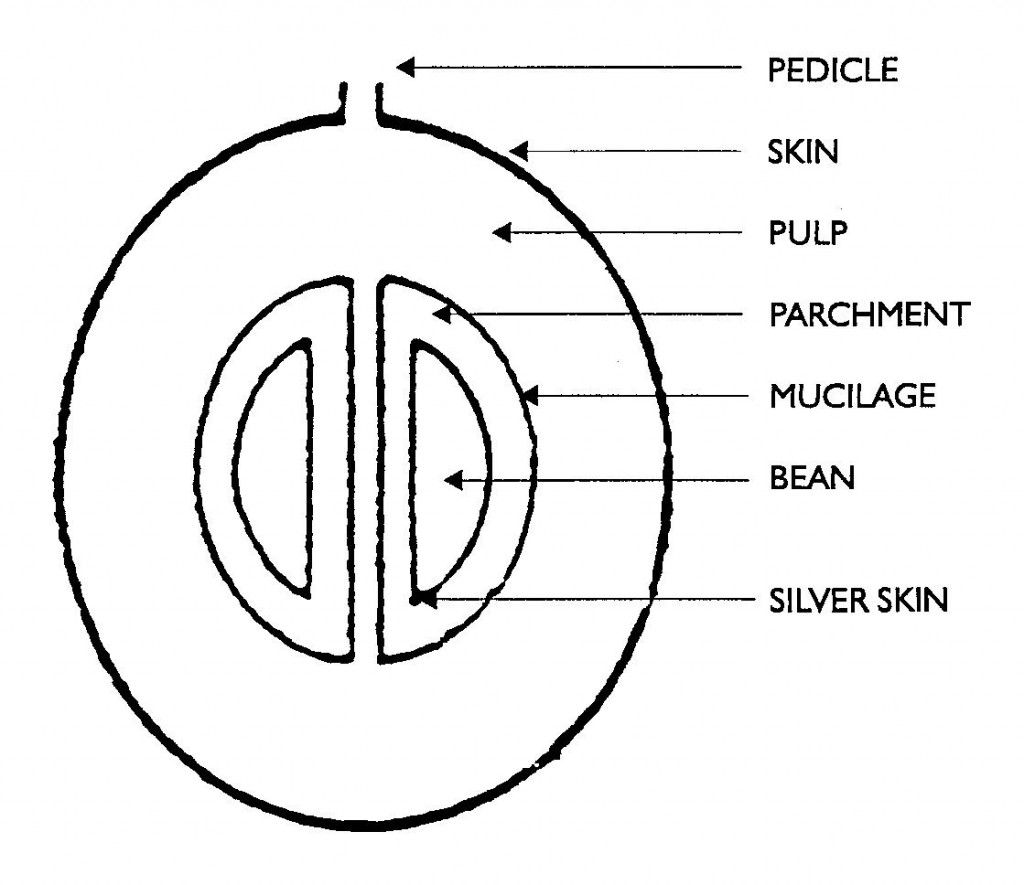

‘The structure of the coffee cherry’ shown below may help you better understand these steps. Production of high quality, wet-processed (washed) arabica coffee depends on careful processing of prime red cherry which is usually selectively handpicked.

Structure of the coffee cherry

Production of high quality, wet-processed (washed) arabica coffee depends on careful processing of prime red cherry which is usually selectively handpicked. Generally, wet-processed ‘washed’ coffees are considered superior to dry-processed ‘unwashed’ coffees. Dry-processed coffee can be very high quality if all the cherry is in prime (ripe) condition and cherry drying conditions are ideal, but it is generally produced under low cost (strip-picking) systems with subsequent lower quality. Dry-processed coffee and coffee originating from overmature cherry are frequently termed `mbuni’ coffees.

Cherry maturity and coffee quality

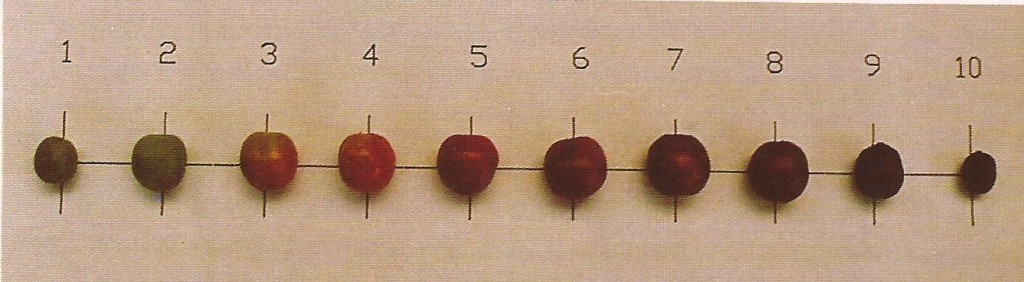

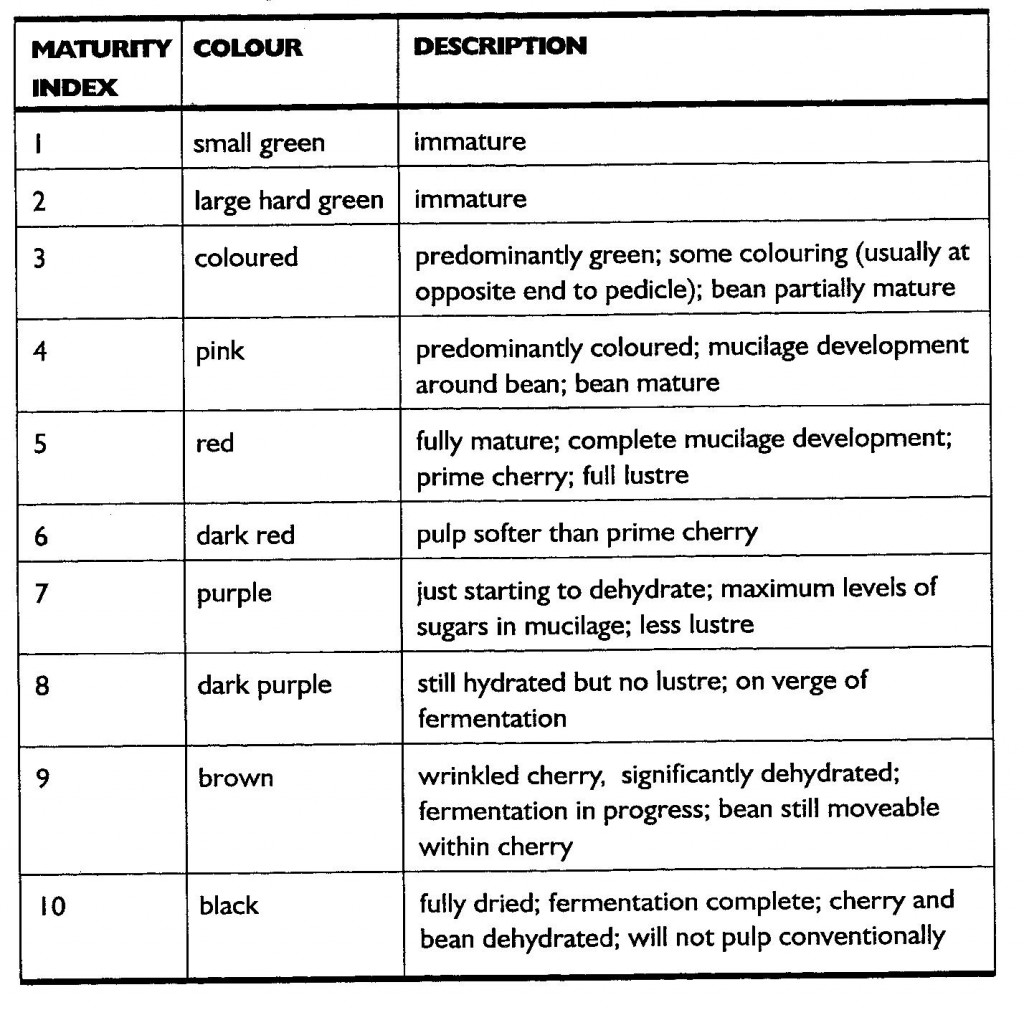

Contamination of prime cherry with immature or overmature cherry during processing will downgrade quality. In Table 3 (below) coffee cherry is classified by maturity into ten stages ranging from small green (stage one) to fully dried black (stage ten). Plate 1 (below) illustrates these same ten maturity stages.

Plate 1 The ten stages of cherry ripening from immature green to overmature (mbuni). The prime ripe state necessary for maximising cupping quality includes stages four to eight.

Wet-processing of stages four to eight produces good quality coffee unaffected by immature or overmature cherry faults. Predominantly pink and coloured cherry (stage four) is acceptable because the bean has fully matured and development of the mucilage layer allows ready pulping. Dark purple cherries (stage eight) will not adversely affect liquor quality provided they have not begun to ferment.

Table 3 Maturity classification of coffee cherry

Source

Craig Lemin