The most realistic goal is highest cherry removal, lowest immature cherry removal, economic operating speed and minimal tree damage

Given the limitations on harvester performance the most realistic goal is to manage the harvester to give the highest ripe cherry removal and lowest immature cherry removal at an economic operating speed with minimal tree damage. Depending on the profile of cherry maturity on the trees at the time of harvest, a number of different operational strategies are possible.

Selective harvesting:

Selective harvesting aims to remove ripe cherry and leave the immature cherry to mature on the tree for removal on a subsequent harvester pass. In berry crops such as blueberries with cultivars developed for machine-harvesting, up to 12 highly selective passes are made to harvest the total crop, with very high recovery of prime fruit. However, multi-pass selective harvesting of current coffee cultivars using the current machine-harvesters is not as successful. For example, at the time of the first pass at Lakeland Downs (see Table below) the trees held approximately 20% overmature cherry, 30% prime cherry and 50% immature cherry. The shaker settings selected for the first pass were a compromise between minimising immature cherry removal and achieving worthwhile mature cherry removal. Shaker settings of 800 cpm, 0.7 km/h, were selected for a high degree of selectivity on the DPI-SP harvester. Approximately 95% of the overmature cherry, 80% of the prime cherry and 40% of the immature cherry on the trees were removed by the harvester. The harvester removed some 62% of the 12 t/ha crop. The sample of cherry off the harvester comprised 30% overmature cherry, 38% prime cherry and 32% immature cherry. The harvester thus showed some degree of selectivity. The levels of immature cherry in the sample cause significant loss of productivity and can cause final product quality problems unless appropriate cherry processing systems are used (see Coffee processing articles).

In field trials, triple pass ‘selective’ machine-harvest treatments have been compared on several occasions with a number of alternative harvesting regimes. A less aggressive first pass than the one used in the Lakeland trial removed less immature cherry at the expense of lower ripe cherry removal. A more aggressive second pass, and an aggressive final pass at approximately four-week intervals, completed the operation.

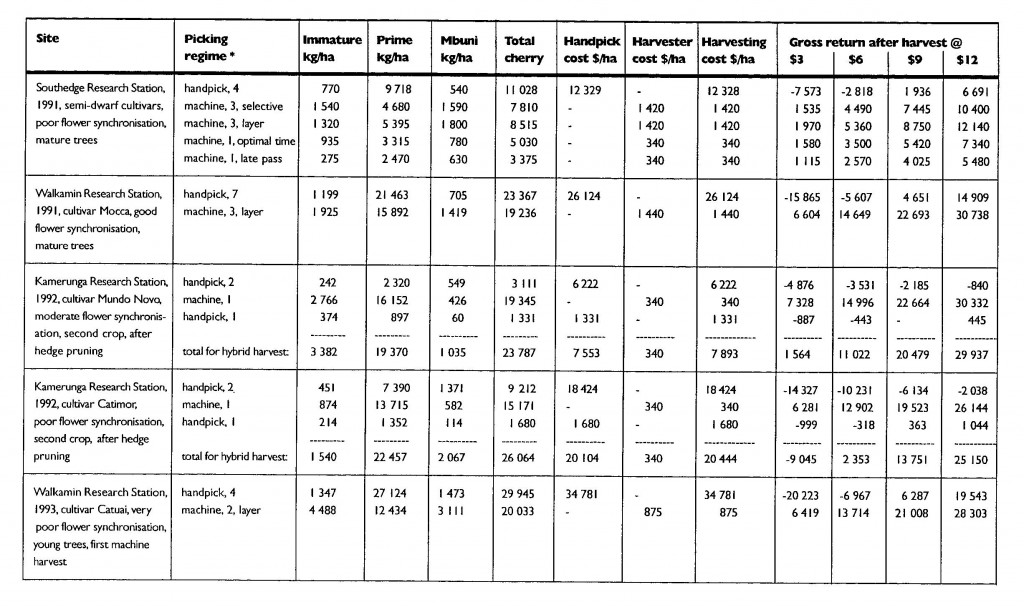

Despite best endeavours, experience has shown that selective harvesting strategies give only a marginal improvement in total recovery over other harvesting strategies (see Table below).

Harvesting costs and recovery of coffee under different harvesting regimes. Refer also to the information below. Walkamin and Southedge data.

Picking regime*

This column indicates the type and number of harvesting passes made (see Table above)

Labour productivity assumptions for hand picking:

Initial 25% of crop harvested at 50 kg/8 hour day (very selective picking, predominantly immature cherry on bush)

• Subsequent 35% of crop harvested at 100 kg/8 hour day (selective picking, greater proportion of mature cherry)

• Remaining 40% of crop harvested at 150 kg/8 hour day (little immature cherry - strip-picking techniques used)

• Labour costs of $12 hour are used

Recovery (based on trial results):

Recovery (based on trial results):

• Immature: 5.5 kg cherry gives I kg green bean - no commercial value

• Prime: 6.5 kg cherry gives I kg green bean - valued at $3, $6, $9 and $ 12/kg green bean, representing the range of prices achieved

by growers

• Mbuni: approx. 3 kg cherry gives I kg green bean - valued at 50% of the selected value of prime green beans

This improvement in recovery must also be balanced against the potential for increased tree damage and higher harvesting costs due to the three harvester passes. Selective harvesting passes are now only used as tools in the harvesting strategy because the first pass hastens ripening and breaks the integrity of the clusters. This conditioning means higher harvesting rates are usually easily achievable in the final harvester pass.

Source:

Chris Norris

This improvement in recovery must also be balanced against the potential for increased tree damage and higher harvesting costs due to the three harvester passes.

Selective harvesting passes are now only used as tools in the harvesting

strategy because the first pass hastens ripening and breaks the integrity of

the clusters. This conditioning means higher harvesting rates are usually

easily achievable in the final harvester pass.