Austoft Harvester

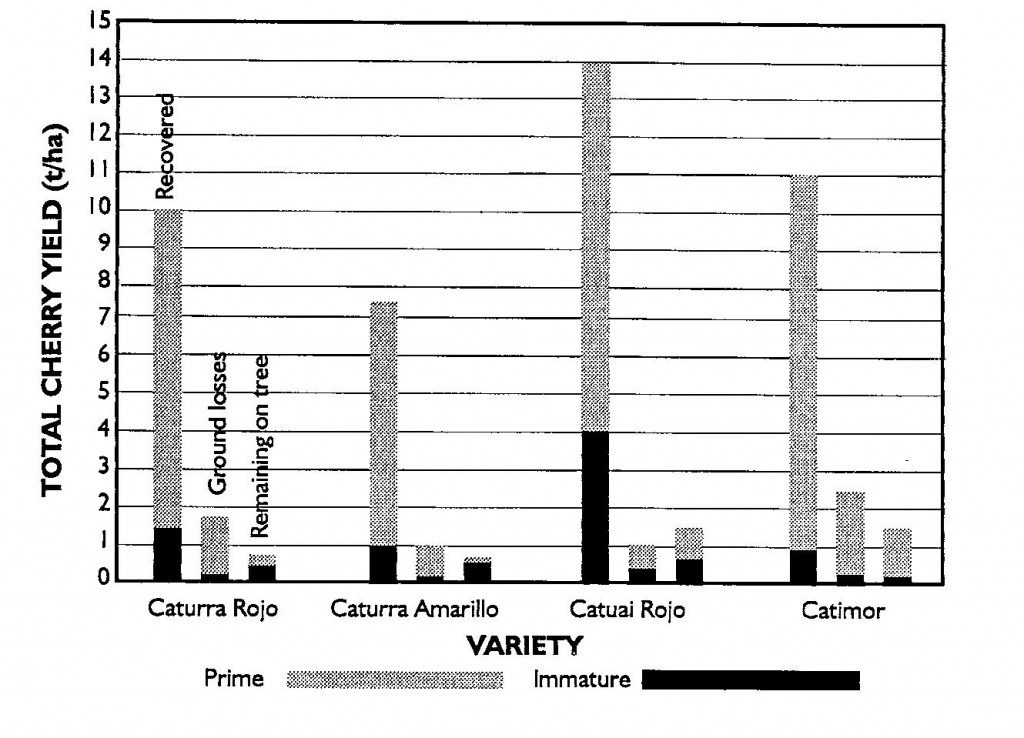

The graph below offers data on the performance of the Austoft harvester operating in trial plots at Kamerunga Research Station in Cairns, North Queensland. The plots included a range of cultivars and all had been previously selectively handpicked. The cherry on cultivar Catimor was very mature, while cultivar Catuai Rojo still held a significant proportion of immature cherry and the maturity of the prime cherry was less advanced than that of the other cultivars.

The data illustrates the high levels of cherry removal possible when maximum selectivity is sacrificed for high cherry removal and harvesting rates. Typically, less than 5% of cherry remained on the trees of the very mature cultivars. These losses increased up to 10% in the cultivars with a greater proportion of immature cherry.

Multiple stemmed trees should be avoided when using machine-harvesters

Losses of cherry to the ground in these trials were consistent with commercial experience, and were typically below 8% of total cherry removed by the shakers. If the cherry collecting system cannot operate properly because of multiple stems (see photo right) or other obstructions, losses can be higher as shown in data for cultivar Catimor. At higher ground speeds, the percentage of cherry lost to the ground through the catching system often increases.

The cherry recovery rates of approximately 3.5 to 7 t/h achieved in these plots is considered a good commercial result, as are the low ground losses and the small amount of cherry remaining on the trees.

Note:

Suckering on the main stem leads eventually to multiple stems. Multiple stems should be avoided when using machine-harvesters because they can reduce harvester efficiency and result in considerable losses from the catching system.

Harvesting performance of Austoft harvester on semi-dwarf cultivars at an operating speed > 1.2km/h (0.5ha/h)

Source:

Chris Norris